Bungalows and Villas

Solutions > Water Softner > Bungalows and Villas

Appointment Timings

Monday - Saturday 10:00 A.M - 07:30 P.M

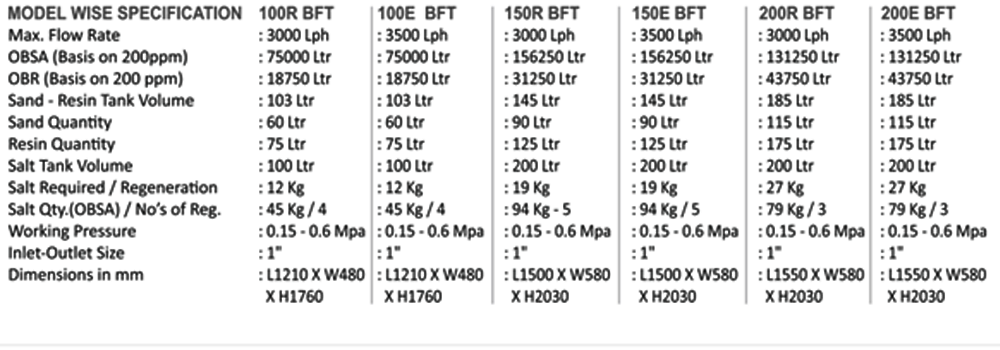

Water Softeners With BFT Technology

In a typical home installation, the water softener is positioned either before or after the storage tank. When the softener is installed after a storage tank, the water gets softened and consumers can use it directly without storing it. However, if the softener is installed before the tank, the water gets stored after the softening process and consumers can use the softened water from the storage tank.

The water softener service mode is based on OBR (volume in litres). When the pre-set OBR volume gets finished, the water softener automatically changes its mode from service to regeneration. The regeneration starts counting down the pre-set time of regeneration until it reaches zero. The softener then returns to the service mode.

The water softener and the pumping storage tank sensors are completely separate devices with zero communication between them. Sometimes during regeneration mode, there might be a shortage of water in the supply tank due to insufficient levels in the groundwater tank. In this situation the pump automatically shuts down while the water softener is continuously counting down its pre-set regeneration time until it reaches zero and then the softener mode will change to service mode. In the actual situation, regeneration does not happen, the resin does not get recharged and does not rinse properly which results in existing salty and dirty water inside the resin tank. Thus, now when the water supply is started, salty and dirty water from the resin tank is released into the softened water storage tank.

To address these issues, PERFECT modified the water softener’s multiport valve by incorporating a low pressure switch input. This modified the multiport valve’s two wires to connect with the (NC) and (C) terminals of the low pressure switch. When there is no water supply to the softeners during the regeneration process, the softener halts the countdown timer until it receives water supply. We call this problem solving innovation ‘The BFT Technology’. Due to this, there is a 100% fully automatic operation, ensuring no entry of dirty and salty water into the soft water storage tank.

Unique Features

- Fully automatic microprocessor-controlling operation

- Incorporated sand filter prevents turbidity to improve efficiency of softener’s resin as well as quality of water

- Display – current time, remaining soft water & current flow

- Brine tank with Brine valve, Brine well and perforated disk

- BFT Technology helps to make fully automated operation with pump, water level controller and Softener

- Incorporated with pressure relief SV and sampling valve

- R Series MPV with big display

- E(Q) Series MPV with Small Display

- Can be used before and after soft water storage tank

- Can be used at individual bungalows

Tank Feeding Systems

These are typically used to fill up different overhead tanks from one central tank.

Tap Feeding

These are used where all the taps are supplied with pressurized water from the central tank.

Curing Systems

These are used during construction period for curing purpose. With this huge amount of water is saved.